Reviews

How Specialised Alloys Improve Processing Durability

Plants in processing industries are always facing pressure to improve efficiency and uptime. This is where specialized alloys play a crucial role by increasing durability in situations where regular materials fail. These metals exhibit greater resistance to wear, corrosion, and high temperatures, thereby significantly prolonging the life of equipment and machinery.

The Importance of Durability in Processing

The industrial environment is often very harsh. Daily, equipment is subjected to heat, moisture, abrasive particles, and chemicals. In short, durability is everything because a breakdown costs money and time. Higher strength and extended service intervals associated with specialized alloys allow businesses to reduce maintenance and keep workflows running smoothly. Therefore, choosing the right alloy becomes significant.

What Makes Alloys Specialized?

Specialized alloys are a mix of two or more metals that possess unique properties. Engineers manipulate the composition to achieve specific results, such as improved hardness or enhanced corrosion resistance. These alloys usually contain elements such as chromium, nickel, or molybdenum, and others to enhance performance in extreme environments. These customized properties surpass those of simple metals, such as copper and aluminum, while making them highly suitable for difficult industrial applications.

Increased Resistance to Corrosion

Regular materials can easily get damaged due to moisture and chemical exposure during processing. Specialized alloys provide better protection against rust and other forms of corrosion. In stainless steel, for example, the chromium forms a layer that protects against moisture. This resistance helps the longevity of machinery and minimizes the possibility of unexpected breakdowns.

Greater Strength and Toughness

Numerous industries require pressure- or impact-resistant materials, or materials that can withstand heavy loads. These specialized alloys are stronger than ordinary metals and exhibit very high resistance to deformation and cracking under stress. Parts made from these materials don’t degrade over time, so you do not have to deal with frequent replacements as well as repairs taking time.

Improved Performance at High Temperatures

Standard metals face significant challenges during heat treatment operations. These specific alloys do not lose their strength or shape in high-temperature environments. Heat-resistant alloys maintain their characteristic features during thermal cycles, preventing conditions for warping or breakage. This solidness provides reliable performance in applications such as chemical processing, power generation, and metalworking.

Prolonged Service Life of Equipment

Equipment that lasts longer means fewer shutdowns and lower operating costs for repairs. The use of specialized alloys minimizes wear and tear, allowing machines to operate as intended for extended periods. Fewer interruptions, higher yields, and better returns on processing equipment investments result from their superior qualities.

Enhanced Safety for Workers

Machines that can be relied on also equate to a safer workplace. Processing plants that experience equipment failure can be hazardous environments to work in, putting employees at risk. This is how specialized alloys help in performing a more secure operation while eliminating the possibility of sudden breakdowns and leaks. Performance consistency controls a safe work environment.

Cost Savings Over Time

Although the upfront cost of specialized alloys may be higher, the long-term value is significantly greater than the initial expenditure. It all translates to less downtime, fewer repairs, and fewer replacements. Companies enjoy enhanced efficiency and reduced downtime, making strategic alloys attractive for a sustained return on investment.

Environmental Benefits

Environmental sustainability is reinforced through the use of durable equipment. If they break down less often, they will produce less waste when parts are discarded. Alloys also mean that units don’t have to be replaced as frequently, which saves resources and lowers the carbon footprint of producing and shipping new units.

Processing Sectors That Benefit

Several processing sectors have embraced specialized alloys to address unique challenges. The chemical industry relies on corrosion-resistant materials to handle aggressive substances. Food processing facilities use alloys that meet strict hygiene standards and resist contamination. Power plants demand heat-resistant metals to withstand intense operational conditions. Each sector benefits from alloys that match its specific requirements.

Continuous Innovation in Alloy Development

The composition of this alloy is not fixed, so material scientists and engineers work to improve it to either enhance known performance or develop new properties and performance. Further research leads to new combinations, even with better properties. That means industries benefit from equipment that is more durable, efficient, and reliable. Specialized alloys will thus continue to find importance in processing durability behind the drive for innovation.

Conclusion

Specialized alloys also enhance durability during processing. Their individual features solve issues in extreme working environments, increase the longevity of equipment, and contribute to a safer workplace. By selecting the proper materials, industries experience fewer disruptions, increased productivity, and long-term savings. Successfully running operations with sustainably beneficial practices starts with investing in specialized alloys.

-

Health6 days ago

Health6 days agoFrance confirms 2 MERS coronavirus cases in returning travelers

-

Health1 week ago

Health1 week ago8 kittens die of H5N1 bird flu in the Netherlands

-

Entertainment6 days ago

Entertainment6 days agoJoey Valence & Brae criticize DHS over unauthorized use of their music

-

US News3 days ago

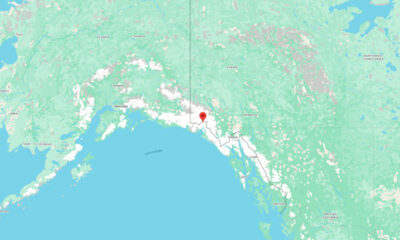

US News3 days agoMagnitude 7.0 earthquake strikes near Alaska–Canada border

-

Legal1 week ago

Legal1 week ago15 people shot, 4 killed, at birthday party in Stockton, California

-

US News1 week ago

US News1 week agoFire breaks out at Raleigh Convention Center in North Carolina

-

Legal5 days ago

Legal5 days agoWoman detained after firing gun outside Los Angeles County Museum of Art

-

Health1 week ago

Health1 week agoEthiopia reports new case in Marburg virus outbreak