Reviews

How Tungsten Carbide is Boosting Renewable Energy Manufacturing

Tungsten carbide has always had a reputation for toughness. It’s used in industries that demand strength, precision, and reliability under pressure. Today, it’s gaining new attention for how it supports renewable energy manufacturing.

Wind, solar, and other green technologies depend on equipment that can last through heavy wear and long operating hours. The materials used to build and maintain that equipment must hold up in difficult conditions. Tungsten carbide, known for its extreme hardness and resistance to heat and abrasion, fits right in.

Across manufacturing lines, tungsten carbide tools and wear parts are now helping engineers cut cleaner, shape faster, and waste less. It’s not just about performance—it’s about how precision and durability feed into sustainability. Fewer tool changes mean less scrap, less downtime, and fewer resources consumed. For companies trying to meet production goals while improving their environmental record, that balance matters.

The renewable energy industry moves fast, but tungsten carbide’s role within it is built on steady reliability. It helps turn high-tech designs into consistent, repeatable products that perform for years in the field.

Why Tungsten Carbide Matters in Modern Manufacturing

Tungsten carbide is made by combining tungsten and carbon at high temperature. The result is a material almost as hard as diamond and much tougher than steel. It keeps its edge even when other materials start to soften or deform under stress.

In manufacturing, that property is a big deal. Cutting tools, dies, and inserts made from tungsten carbide can handle continuous machining with minimal wear. They hold tight tolerances, which is essential in precision manufacturing.

This same reliability has become important in renewable energy production. Wind turbines, solar panels, and green tech machinery are made from advanced composites and high-strength alloys. These materials are difficult to cut or shape using traditional tooling. Carbide tooling maintains dimensional accuracy, even when machining abrasive surfaces or high-temperature alloys.

For engineers, that stability translates to fewer production disruptions and more consistent part quality. Over time, it reduces waste, improves production speed, and supports the sustainable use of raw materials.

Tungsten Carbide in Wind Turbine Production

The wind energy sector depends on components that endure harsh environments like salt air, shifting temperatures, and constant mechanical stress. Tungsten carbide helps at several stages of turbine production and operation.

During manufacturing, carbide cutting and trimming tools are used to process the large composite blades. These blades are often made of fiberglass or carbon fiber reinforced polymers, which can quickly dull standard steel tools. Tungsten carbide retains its edge for far longer, allowing cleaner cuts and smoother surfaces. Those clean edges improve aerodynamic efficiency once the turbine is in use.

The material also appears inside the turbines themselves. Bushings, bearing surfaces, and seal components made from tungsten carbide handle the friction and load stress of continuous motion. When these parts last longer, maintenance intervals are extended and downtime drops. That reliability supports not just production efficiency but also the sustainability goals of energy providers who depend on long operating cycles.

Manufacturers have learned that every hour saved on retooling or repairs contributes to lower overall energy consumption in production. In this way, the toughness of tungsten carbide becomes part of a broader strategy for environmental efficiency.

The Role of Tungsten Carbide in Solar Panel Manufacturing

Solar manufacturing is all about precision. The wafers used in solar panels are delicate and thin, often less than a millimeter thick. Any crack or imperfection can reduce their ability to generate power.

Tungsten carbide tools are critical in cutting, shaping, and polishing these wafers. The material’s strength ensures clean, controlled cuts without causing microfractures. That precision helps improve overall yield and reduces scrap, both important for cost and sustainability.

Carbide tooling is also used in frame and junction box production. Metal frames around solar panels must fit perfectly, often with automated assembly. Tungsten carbide punches and dies keep consistent tolerances through thousands of cycles without deforming. That consistency keeps automated production lines running smoothly and reduces rejected parts.

Green Technology Machinery and Production Efficiency

Beyond wind and solar, tungsten carbide manufacturing supports a range of clean technologies. Electric vehicle systems, hydrogen components, and recycling machinery all rely on high-performance materials that must endure continuous stress.

When machining EV housings, motor parts, or fuel system valves, carbide tooling provides stable performance at high speeds. It handles thermal expansion and vibration better than most metals, keeping tolerances tight. The result is less rework and a smoother finish, which means fewer wasted parts.

In recycling and biomass processing equipment, tungsten carbide shows up again. Conveyor systems, chutes, and pumps that move abrasive materials use carbide coatings to reduce wear. These coatings help extend maintenance intervals, keeping operations efficient and minimizing energy use.

The benefits go beyond simple durability. When production lines operate with less friction and longer tool life, they consume less electricity and raw material. That’s where performance meets sustainability. Tungsten carbide makes it possible for manufacturers to stay competitive while aligning with environmental targets.

Sustainability Through Material Efficiency

Although tungsten itself is a mined resource, its use in manufacturing contributes to sustainability through longevity and recyclability. Unlike many industrial materials, tungsten carbide can be reclaimed without losing its core properties.

Used carbide tools are often collected, crushed, and processed back into powder. That powder is then sintered into new components. The process saves natural tungsten reserves and significantly reduces the environmental footprint of manufacturing. Many major carbide producers now run closed loop recycling programs that recover valuable material from worn tools.

Durability is another part of its sustainability story. Every time a carbide tool outlasts a steel one by a factor of ten, it prevents more material from entering the waste stream. Less scrap metal means less energy spent on refining, melting, and reforming new alloys. For factories that run around the clock, that energy savings adds up fast.

Energy efficiency also comes from precision. Because tungsten carbide maintains sharpness longer, machining requires less force, reducing energy consumption at the spindle. It’s not dramatic or flashy, but it’s measurable, and that’s exactly what sustainability in manufacturing is about, practical improvements that add up over time.

The Future of Tungsten Carbide in Green Tech

Looking ahead, tungsten carbide will likely remain central to renewable manufacturing. It’s already proven in high-demand applications, and as new energy systems emerge, its role will only grow.

Researchers are experimenting with advanced binder systems and finer grain structures to improve toughness without losing hardness. These refinements could lead to tools that last even longer or perform in more extreme conditions. That’s especially valuable for wind and solar equipment, where precision and longevity directly affect energy yield.

There’s also progress in coating technologies. Thin carbide or nano-carbide layers on steel substrates allow engineers to get many of the benefits of solid carbide without the full cost or weight. These coatings could expand tungsten carbide’s use in larger, cost-sensitive applications.

The more renewable systems grow, the greater the demand for stable and recyclable materials. Tungsten carbide manufacturing provides reliability and efficiency that align with modern sustainability goals.

In Conclusion

Tungsten carbide’s story in renewable energy isn’t about breakthroughs or sudden changes. It’s about steady improvement. In wind turbines, solar panels, and green machinery, it supports manufacturing processes that need precision, strength, and efficiency.

Through recycling and longer tool life, tungsten carbide also supports sustainability in ways that make sense for industry. It helps reduce waste, cut energy use, and improve production consistency. Quiet but important contributions to a cleaner economy.

As manufacturing continues to evolve, materials like tungsten carbide show that durability and environmental responsibility can work together. It’s a reminder that sustainable progress often starts with the tools we use to build it.

-

Health6 days ago

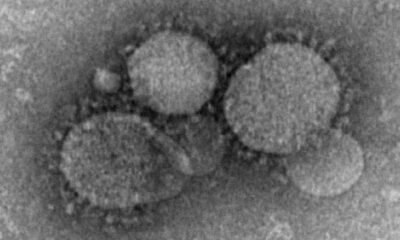

Health6 days agoFrance confirms 2 MERS coronavirus cases in returning travelers

-

Health1 week ago

Health1 week ago8 kittens die of H5N1 bird flu in the Netherlands

-

Entertainment6 days ago

Entertainment6 days agoJoey Valence & Brae criticize DHS over unauthorized use of their music

-

US News3 days ago

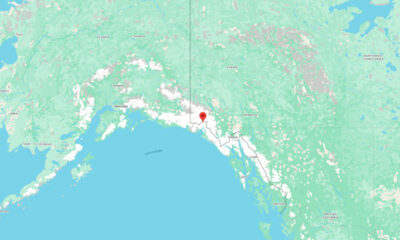

US News3 days agoMagnitude 7.0 earthquake strikes near Alaska–Canada border

-

Legal1 week ago

Legal1 week ago15 people shot, 4 killed, at birthday party in Stockton, California

-

US News1 week ago

US News1 week agoFire breaks out at Raleigh Convention Center in North Carolina

-

Legal5 days ago

Legal5 days agoWoman detained after firing gun outside Los Angeles County Museum of Art

-

Health7 days ago

Health7 days agoEthiopia reports new case in Marburg virus outbreak