Reviews

How Flow Meters Improve Efficiency and Cut Costs in Industrial Operations

Ever wonder how factories keep the flow of liquids and gases transferring through their systems? In commercial operations, monitoring these flows is greater than just checking meters – it is about controlling charges, lowering waste, and keeping machines going for walks easily.

A flow meter performs a key role in that. In this article, we will cover what a flowmeter is, how it works, why it’s vital to the fee and operational efficiency, and how to pick out and keep one so your business process runs more smoothly.

What is a Flow Meter?

A flow meter is a device designed to measure the quantity of liquid or gas passing through a pipe or line. In many commercial settings, the size may be what number of liters in step with minute, how many cubic meters in step with hour, or how many kilograms of gasoline in step with second that are moved.

The device offers records in real time. Having these facts means the operator can see when matters are off beam, including too much flow, too little go with flow, or modifications in fluid properties.

Why Flow Meters Matter in Industrial Operations

Here are some of the ways a flow meter matters in an industrial setting:

- Resource use under control. When you know exactly how much fluid is flowing, you avoid overusing or underusing materials.

- Waste reduction. If there are leaks, irregularities, or unintended flows, you’ll spot them earlier via flow measurement.

- Energy savings. Many processes use pumps, compressors, or other equipment that move fluid. If you optimize the flow, you can reduce energy consumption.

- Quality assurance. In manufacturing, the correct amount of fluid matters (for example, in chemical dosing, mixing, and cooling). A proper flow meter helps maintain consistent product quality.

- Better decision‑making. Flow data gives you visibility into what’s truly happening, not just guesses. This helps plan maintenance, control cost, and improve uptime.

How Flow Meters Improve Efficiency and Cut Costs

In industries in which precision and resource control are essential, go with flow meters are game-changers, slashing waste and boosting operational performance. By presenting correct, actual-time statistics on the glide of drinks, gases, or steam, these devices cast off the highly-priced guesswork that results in overuse, energy loss, and unexpected downtime. Here’s how flow meters deliver measurable savings and streamline methods:

1. Minimize Material Waste

Whether you’re dosing chemical compounds in water remedy, blending ingredients in food production, or coping with gas in electricity structures, specific glide size ensures you operate exactly what’s needed—no more, no less. Over-dosing or under-dosing can lead to scrapped batches or a pricey remodel. Flow meters help you hit the mark on every occasion, decreasing fabric prices and boosting profitability.

2. Optimize Energy Consumption

Pumps, compressors, and other devices frequently run harder than necessary because of faulty waft estimates. Flow meters permit you to great-track those systems, making sure they function at peak performance. By matching output to real demand, you lessen power intake, decrease application bills, and extend system lifespan through minimizing wear and tear.

3. Proactively Detect Issues

Flow meters act as an early warning system. Sudden adjustments in float fees—whether or not a drop signals a clog or a spike indicates a leak—alert you to capability problems before they develop into expensive repairs or production halts. This real-time insight helps you cope with problems unexpectedly, preserving operations running smoothly.

4. Smarter Maintenance Scheduling

Traditional maintenance schedules regularly cause pointless servicing or neglected troubles. With drift meters, you may undertake condition-based protection, servicing the system handiest whilst data indicates a problem. This technique cuts hard work costs, reduces downtime, and prevents untimely wear on important systems.

5. Ensure Consistent Product Quality

Inconsistent flow can disrupt approaches like mixing, heating, or cooling, mainly to off-spec merchandise that fail first-class exams. Flow meters hold constant, specific waft fees, making sure your output meets specs on every occasion. This reduces waste from rejected batches and strengthens consumer acceptance as true for your product’s reliability.

6. Simplify Installation and Integration

Modern drift meters, together with non-intrusive clamp-on ultrasonic fashions, can be set up without reducing pipes or halting production. This minimizes installation expenses and downtime at the same time while taking into consideration flexible retrofitting in existing structures. Advanced fashions also combine seamlessly with virtual control structures, offering actionable statistics for further system optimization.

By delivering precision, reliability, and actionable insights, glide meters now not most effectively cut expenses but also enhance ordinary operational efficiency. Investing within the proper waft meter tailor-made to your utility can yield rapid returns, making it a smart preference for any cost-aware, performance-driven operation.

Practical Steps to Choose a Flow Meter in Your Plant

Here’s a checklist to manual you when you decide to use or update a float meter:

– Identify the fluid or gasoline you need to degree: is it water, steam, a chemical, or a slurry? What are its homes (conductivity, viscosity, temperature, strain)?

– Define the glide charge range: what’s the minimum glide you may see, what’s the maximum? The meter needs to take care of that variety.

– Consider the installation surroundings: pipe size, immediate pipe run upstream and downstream, right of entry for upkeep, and presence of vibration or electromagnetic interference.

– Decide whether or not you want volumetric, go with the flow (litres consistent with minute), or mass flow (kg per 2d). Some applications want mass glide for accuracy whilst density changes.

– Look at accuracy and repeatability: how particular does the dimension need to be? What’s an appropriate blunder?

– Choose a meter type that fits the fluid and set up: for example, if the fluid has particles or bubbles, some meter types won’t paintings as well. When you want to measure the flow of water, you need to use a water flow meter.

– Think about protection and overall cost of possession: initial cost is one aspect, but service, calibration, downtime, and compatibility are also considered.

Installing and Taking Care of a Flow Meter

- Place the meter on a straight section of pipe — not too close to bends, valves, or pumps. This helps it read flow more accurately.

- Avoid mounting it where the fluid flow is likely to be turbulent or unstable, like right after a sharp turn or an open valve.

- Make sure the pipe is clean and in good condition before installing the meter — dirt or corrosion can throw off readings.

- Protect electrical connections from moisture and dust, especially in environments with heat, vibration, or chemicals.

- Once installed, get familiar with what “normal” readings look like. That way, unusual values will stand out immediately.

- Don’t skip scheduled cleaning and calibration. Even a good meter will drift over time or collect buildup inside.

- Teach your team how to read the data and what steps to take when flow numbers change. The meter is only helpful if someone uses the info.

Mistakes Beginners Should Watch Out For

- Picking a meter just because it’s cheap without checking if it fits your fluid type, pressure, and flow range.

- Installing it in a bad location — for example, near sharp turns, pumps, or places where the fluid doesn’t move steadily.

- Forgetting that fluids can change. Some meters don’t handle thick or hot liquids well if those conditions shift often.

- Skipping routine checks. If debris builds up inside the meter, it may keep working but give bad readings.

- Treating the meter like a fix-all. It won’t reduce waste or cut energy costs unless someone actually uses the data it gives.

What to Expect in Terms of Savings

While every commercial operation is one-of-a-kind, here are a few sensible benefits you might see from a proper flow meter implementation:

- Reduction in raw fluid usage: by avoiding excess flow or leaks.

- Lower energy cost: by tuning pumps, valves, and reducing unnecessary flow.

- Reduced downtime: by spotting abnormal flow early and acting.

- Improved product consistency: less waste from off‑spec products.

- Lower maintenance cost: fewer emergency repairs and more planned work.

Final Thoughts

Using a flow meter in a commercial place is more than just putting a device on a pipe. It’s about making the invisible movement of fluids seen, so you can control it, lessen waste, store power, and maintain dependable output.

As an amateur, recognition of selecting the proper kind, installing it nicely, the use of the readings to guide your moves, and keeping everything maintained. When you do, you’ll see actual savings and smoother operations.

-

US News2 days ago

US News2 days agoJetBlue flight diverts to Tampa after altitude drop injures at least 15

-

US News1 week ago

US News1 week agoUnwarned tornado suspected in Fort Worth as storms cause damage and power outages

-

World6 days ago

World6 days agoU.S. Navy helicopter and fighter jet crash in South China Sea; all crew rescued

-

Legal7 days ago

Legal7 days agoMultiple injured in shooting at Lincoln University in Pennsylvania

-

US News3 days ago

US News3 days agoTrump says U.S. will resume nuclear weapons testing ‘on an equal basis’

-

US News4 days ago

US News4 days agoDamage reported in Kilgore, Texas following tornado warning

-

World6 days ago

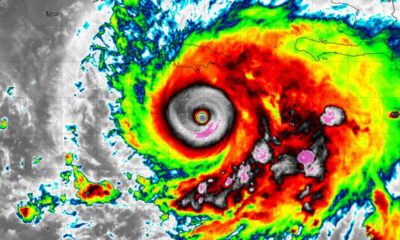

World6 days agoMelissa could make landfall in Jamaica as a Category 5 hurricane

-

Legal4 days ago

Legal4 days ago3 killed in murder-suicide involving Wright-Patterson Air Force Base personnel