Reviews

Steps to Properly Load Refrigerated Shipping Containers

Refrigerated shipping containers, also known as reefers, are essential for transporting perishable goods such as fruits, vegetables, dairy, meat, seafood, and pharmaceuticals. These containers maintain a controlled temperature, ensuring that the contents remain fresh and safe throughout their journey.

Proper loading is critical to ensure optimal cooling, prevent spoilage, and avoid damage during transit. Mishandling the loading process can lead to inconsistent temperatures, compromising the quality of the goods.

This article will walk through the key steps to properly load refrigerated shipping containers to maximize efficiency and maintain product quality.

1. Pre-Inspect the Container

Before loading begins, it’s essential to inspect the refrigerated container to ensure it is in good working condition and clean.

Check for Cleanliness

- Interior Condition: The interior of the container should be free from dirt, debris, and any residual odors from previous loads. Any contamination could compromise the freshness and safety of your goods.

- Odor Check: Ensure there are no lingering smells from previous cargo, which may affect the integrity of the perishable items being loaded.

Ensure Functionality

- Temperature Settings: Test the refrigeration unit to ensure it can maintain the desired temperature range for your cargo. Reefers typically offer temperature control between -30°C and +30°C (-22°F to +86°F), depending on the product requirements.

- Airflow System: Ensure the airflow system is functioning correctly. Adequate airflow is critical in maintaining consistent temperatures throughout the container.

- Damage Inspection: Look for any physical damage to the walls, doors, or floor that may cause temperature leaks or compromise structural integrity. Seal any gaps or cracks that could affect insulation.

2. Pre-Cool the Container

To prevent spoilage or temperature fluctuations during loading, it is essential to pre-cool the reefer to the required temperature.

Why Pre-Cooling Matters

- Temperature Stability: Pre-cooling ensures that the container starts at the desired temperature before the cargo is loaded. Without pre-cooling, the refrigeration unit may struggle to cool the air fast enough, especially with sensitive perishable goods.

- Preventing Heat Transfer: When the container is at the correct temperature, the products remain cool during the loading process. Loading directly into a warm container can increase the internal temperature and compromise product quality.

Pre-Cooling Process

- Run the Refrigeration Unit: Activate the reefer’s refrigeration system and allow it to cool down to the required temperature. This process typically takes between 30 minutes to several hours, depending on the desired temperature and external conditions.

- Monitor the Temperature: Continuously monitor the internal temperature to ensure it stabilizes at the correct level before beginning to load.

3. Use Pallets or Floor Gratings for Air Circulation

Proper airflow is key to maintaining a uniform temperature throughout the container. Pallets or floor gratings are crucial to facilitate this.

Importance of Pallets

- Airflow Under Cargo: Pallets create space between the cargo and the floor of the container, allowing cool air to circulate beneath and around the products. This prevents cold spots and helps maintain consistent temperatures throughout the load.

- Prevent Blockages: Stacking goods directly on the floor can block airflow and cause uneven cooling, leading to hotspots and spoilage.

Selecting Pallets

- Standard Size: Ensure pallets are of standard size and are not broken or damaged. Damaged pallets could cause product instability and compromise airflow.

- Non-Toxic Materials: Choose pallets made from non-toxic materials, especially when transporting food or pharmaceuticals, to prevent contamination.

4. Stack and Load the Cargo Correctly

How you stack and load the cargo inside the refrigerated shipping container directly affects the cooling efficiency.

Leave Space for Airflow

- Space Between Walls and Roof: Leave a gap between the cargo and the container walls and ceiling to ensure adequate air circulation. Avoid stacking goods too close to the ceiling, as this can block the return air, preventing uniform cooling.

- Create Channels: Arrange the goods in a way that allows airflow to circulate throughout the container. Consider using a method such as “T-lining” (loading goods in rows) to promote even cooling.

Distribute Weight Evenly

- Balanced Weight Distribution: Ensure the weight is evenly distributed throughout the container to prevent shifting during transit. Overloading one side or area can affect the container’s structural integrity and the functioning of the refrigeration unit.

- Fragile Goods: If transporting fragile goods, stack heavier items on the bottom and lighter items on top to avoid crushing.

5. Use Proper Packaging Materials

Packaging plays a crucial role in maintaining the integrity of perishable goods during transport.

Insulated Packaging

- Temperature-Controlled Packaging: For temperature-sensitive goods, use insulated or thermal packaging to provide an extra layer of protection. Insulated packaging helps maintain the core temperature of the goods, even during brief temperature fluctuations.

Moisture-Resistant Materials

- Waterproof Packaging: Choose packaging that is moisture-resistant to prevent damage caused by condensation inside the container.

- Secure Sealing: Make sure all packages are tightly sealed to prevent leakage or exposure to external air, which could compromise the temperature stability.

6. Monitor Temperature During Loading

Temperature monitoring during the loading process ensures that perishable goods remain at the optimal temperature throughout.

Use Temperature Sensors

- Install Sensors: Place temperature sensors or data loggers in various locations inside the container to monitor internal temperatures during loading and transit.

- Monitor Fluctuations: Keep an eye on any sudden changes in temperature. Even slight fluctuations during loading can affect sensitive perishable items.

Minimize Door Opening Time

- Quick Loading: Open the container doors only when necessary, and aim to complete the loading process as quickly as possible to minimize warm air entering the container.

- Cold Loading Area: If possible, load the reefer in a temperature-controlled environment or shaded area to reduce the effect of external heat.

7. Seal the Container Securely

Once the container is fully loaded, securely seal it to maintain temperature control and prevent theft or tampering.

Check for Proper Sealing

- Inspect Door Seals: Ensure the container’s door seals are intact and functioning properly to prevent cold air from escaping and warm air from entering.

- Apply Security Seals: For additional security, apply tamper-evident seals or locks to the container doors to prevent unauthorized access.

8. Monitor Temperature Throughout Transit

Once the container is on its way, it’s important to continue monitoring the temperature to ensure the integrity of the cargo.

Remote Monitoring

- GPS and Temperature Tracking: Many modern refrigerated containers come equipped with remote monitoring capabilities. These systems allow you to track both the location of the container and the internal temperature in real time.

- Alerts: Set up alerts for temperature fluctuations, so you can act immediately if the container’s internal temperature rises or falls outside the desired range.

Load Refrigerated Shipping Container Properly

Properly loading refrigerated shipping containers is essential for ensuring that perishable goods reach their destination in optimal condition. By pre-inspecting the container, ensuring adequate airflow, using the correct packaging, and carefully monitoring temperature during loading and transit, you can help prevent spoilage, extend shelf life, and reduce losses.

Following these steps will ensure that your products remain safe, fresh, and high quality, making your refrigerated shipping operations more reliable and efficient.

-

World3 days ago

World3 days agoEthiopian volcano erupts for first time in thousands of years

-

Legal1 week ago

Legal1 week agoMichigan man JD Vance sentenced to 2 years for threatening Trump and JD Vance

-

Legal1 week ago

Legal1 week agoWoman in critical condition after being set on fire on Chicago train

-

World1 week ago

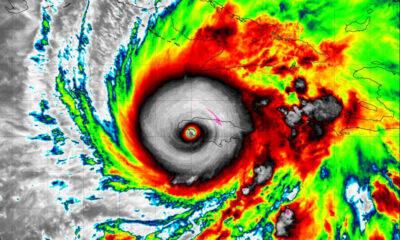

World1 week agoHurricane Melissa registered 252 mph wind gust, breaking global record

-

Legal8 hours ago

Legal8 hours agoUtah Amber Alert: Jessika Francisco abducted by sex offender in Ogden

-

Legal6 days ago

Legal6 days agoSuspect in San Diego stabbing shot by authorities after fleeing into Mexico

-

Legal1 week ago

Legal1 week ago1 dead, 2 injured in shooting at Dallas Walmart parking lot

-

Health6 days ago

Health6 days agoMarburg virus outbreak in Ethiopia grows to 6 confirmed cases