Reviews

Forklift Safety Essentials: Best Practices for Warehouses and Construction Sites

When a road roller has done its job, the next stage is making sure materials move safely and efficiently across the site. That hand-off is where forklifts earn their keep. If used well, they speed work and keep schedules on track. If used poorly, they cause damage, injury and costly delays.

Forklift Safety: Why It’s So Important

Forklifts are everywhere because they work. They carry pallets, move bulky loads, stack materials and keep projects moving. But the power they bring carries real risk. When something goes wrong, the consequences can be severe. They can be life-changing injuries, damaged stock, site shutdowns and legal exposure. Recent industry tracking shows that lift trucks continue to be a significant source of workplace injuries. This is why prevention and training are non-negotiable.

Core rule: train well, then trust what training teaches

At the heart of every safe site is competent, certified operators. Employers bear the responsibility to train, assess and document competency — classroom learning needs to be paired with hands-on practice and evaluated driving. Training should be refreshed if conditions change (new equipment, different loads, new surfaces) and should cover not only how to drive but how to read a scene: spotting weak flooring, anticipating pedestrian movements, and understanding load stability. Clear records and periodic reassessments turn training from a box-ticking exercise into an everyday safety habit.

Daily checks that actually prevent problems

A short, focused pre-shift inspection saves time and lives. Operators should make a short walk-around before every shift: check brakes, steering, lights, horn, forks, mast chains, tyres (or wheels), warning devices and fluid levels. If anything looks off, tag it out and notify maintenance — even small leaks or a loose clamp can escalate into a big failure under load. Using a consistent checklist keeps the habit reliable and helps supervisors track recurring faults that indicate broader equipment issues.

Forklift operation: straightforward tactics that reduce accidents

Mid-shift behaviour matters more than heroic driving. Always keep these practical habits in front:

- Carry loads low and tilted back slightly while moving — it keeps the centre of gravity safer.

- Slow down on corners and use the horn or lights at blind intersections. If the load blocks view, drive in reverse or use a spotter.

- Avoid sudden starts or stops, and don’t raise or lower forks while travelling. These small moves are where most mishaps begin.

These are not exotic rules — they’re the basics that prevent the majority of incidents.

Pedestrian safety and simple traffic management

A busy warehouse or site with passing crews needs clear separation. Mark walkways, use barriers where possible, and institute right-of-way rules. Train pedestrians to stand clear when vehicles approach. Equip the forklift with audible alarms so nobody is surprised. Regularly review routes as site layout changes. A temporary loading bay can become a permanent hazard if ignored.

Adapting to site realities: warehouse vs construction

A well-paved warehouse aisle and a muddy construction yard demand different caution. On sites you must expect uneven terrain, weather changes, loose loads and the presence of larger plants (dumpers, rollers). That means:

- Reduce speed on wet ground and allow extra stopping distance.

- Secure irregular loads and use timber or straps where needed to prevent shifting.

- Coordinate movement near other heavy plants — set up clear exclusion zones when a road roller or crane is working nearby.

- Use supervisors or banksmen to guide vehicles in tight or congested zones.

The same rules apply across settings but the margin for error shrinks on rough ground — plan accordingly.

Maintenance, reporting and simple tech that helps

Preventive maintenance is the quiet safety hero. A scheduled program for oil, filters, tyres, and hydraulics prevents many sudden failures. Encourage a reporting culture: a small fault reported today is a big accident avoided tomorrow.

Real examples, real outcomes

Teams that treat safety as a core process — with regular checks, solid training and simple traffic control — report fewer lost-time incidents and less damage to stock and buildings. Supervisors who walk the floor, listen to operators and fix small problems quickly build trust; operators who feel supported are more likely to report faults and follow procedures. The payoff is not just fewer insurance claims: it’s a smoother, faster operation where everyone goes home whole.

Conclusion

Forklifts are a productivity backbone for construction sites. When operators are trained those same forklifts become a source of reliable progress rather than risk. Think of it like the flow of a well-run site: a road roller sets the base, forklifts keep materials moving, and specialist kit such as a boom lift can give safe access up high — each tool doing its part so the whole job finishes clean, on time and without harm.

-

Legal6 days ago

Legal6 days agoMichigan man JD Vance sentenced to 2 years for threatening Trump and JD Vance

-

Politics1 week ago

Politics1 week agoU.S. to designate Maduro-linked Cartel de los Soles as terrorist organization

-

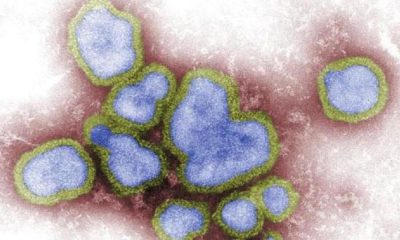

Health7 days ago

Health7 days agoCambodia reports fatal H5N1 bird flu case in 22-year-old man

-

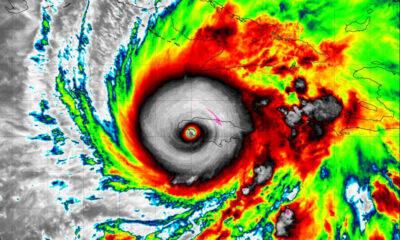

World4 days ago

World4 days agoHurricane Melissa registered 252 mph wind gust, breaking global record

-

Legal4 days ago

Legal4 days agoWoman in critical condition after being set on fire on Chicago train

-

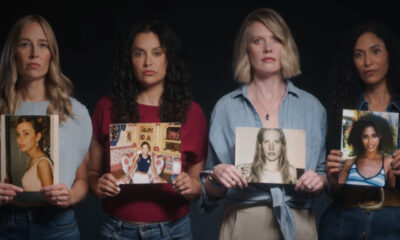

Politics7 days ago

Politics7 days agoEpstein survivors release PSA calling on Congress to release all files

-

Legal4 days ago

Legal4 days ago1 dead, 2 injured in shooting at Dallas Walmart parking lot

-

Legal3 days ago

Legal3 days agoSuspect in San Diego stabbing shot by authorities after fleeing into Mexico