Reviews

The Power of Intelligent Automation for Industrial Manufacturing

From adaptive robotics that respond to real-time production data to AI-driven predictive maintenance that minimizes downtime, intelligent automation is revolutionizing industrial manufacturing by enhancing efficiency and precision in processes like rapid manufacturing and metal machining. This technology integrates artificial intelligence, robotics, and data analytics to streamline operations, reduce costs, and improve product quality. By leveraging these advanced tools, manufacturers can meet growing demands while maintaining a competitive edge.

Transforming Rapid Manufacturing

Intelligent automation is transforming rapid manufacturing, making it possible to achieve faster production cycles and reduced lead times. Real-time data is used to change workflow to produce components fast and correctly, by automated systems. This dynamic model reduces downtimes, maximizes production and gives the flexibility required in industries that have to react at a very fast rate to the market changes.

The intelligent automation is also efficient in the use of materials, which minimizes waste and decreased the overall costs. Machines that have AI capabilities are able to forecast the demand of materials and adjust settings dynamically, enabling manufacturers to increase the volume of production at a reasonable cost without compromising quality.

Robotics also add increased accuracy and uniformity to the quick production. Complex designs are handled easily by automated tools thus eliminating human error and ensuring that each product is of high quality. Coupled with speed, accuracy and intelligent management of resources, rapid manufacturing provides quality and reliable results at a speed that stimulates innovation and competitive development.

Enhancing Metal Machining Processes

The introduction of intelligent automation in metal machining is causing a significant change in the industry, producing more accurate, efficient, and durable finished products. AI-based systems constantly check cutting conditions, including tool wear, vibration, and temperature, and change parameters, such as spindle speed and feed rate, in real-time. Such dynamic changes guarantee the quality of outputs and prolong the life of the tools, as well as shortening unwarranted downtimes.

Automation is also energy efficient through the optimization of tool paths and cutting processes. Sensors identify inefficiencies and self-adjust processes in order to minimize power use and material wastes. It is able to reduce operational costs, as well as match metal machining with sustainable manufacturing, which is becoming an important aim of modern industries.

Robotics also reinforce the process by performing heavy workloads and complex tasks in an exceptionally accurate manner. Robotic arms can perform repetitive tasks that include loading, unloading and complex cutting, allowing human operators to concentrate on programming, monitoring and innovation. This synergy between intelligent systems and human operators enhances production capacity, ensures that quality is controlled in large batches and allows manufacturers to sustain increasing market demands in a fast and reliable manner.

Boosting Operational Efficiency

In sectors such as rapid manufacturing and metal machining, automated systems handle repetitive tasks with speed and precision, freeing skilled workers to focus on strategic challenges and innovative solutions. This balanced allocation of human and machine effort drives higher productivity while reducing fatigue-related errors.

Advanced data analytics embedded within intelligent automation provides real-time insights that enhance decision-making. Manufacturers can monitor key performance metrics, detect inefficiencies, and identify production bottlenecks instantly. This proactive oversight supports continuous improvement, enabling teams to make quick adjustments that keep operations running smoothly.

Reducing manual interventions also minimizes production errors. Automated systems follow programmed instructions with exceptional accuracy, ensuring consistent quality across every batch. This reliability is critical for meeting customer expectations, protecting market reputation, and maintaining competitive advantage. By combining data-driven insights with automated precision, intelligent automation delivers operational efficiency that supports long-term growth and scalability.

Improving Product Quality and Consistency

Intelligent automation elevates product quality in rapid manufacturing and metal machining by maintaining precise control over every production stage. AI-driven algorithms continuously analyze real-time data, detecting even the smallest deviations and making instant corrections. This ensures that every component meets or exceeds strict industry standards, reducing the need for rework or costly recalls.

Automated inspection systems further strengthen quality control. Equipped with advanced machine vision, these systems detect surface flaws, dimensional errors, and hidden defects that human inspectors might overlook. By ensuring that only flawless products leave the production line, manufacturers enhance brand reputation and boost customer satisfaction.

Consistency across production batches is another key benefit. Standardized, automated processes eliminate variability in machining and assembly, delivering uniform results with each cycle. This reliability is especially critical in industries such as aerospace, automotive, and medical devices, where safety, precision, and performance depend on unwavering product quality and consistency.

Reducing Costs and Downtime

Intelligent automation lowers costs in rapid manufacturing and metal machining by optimizing resource use. Automated systems reduce material waste and energy consumption, directly impacting the bottom line. This cost efficiency allows businesses to reinvest savings into growth initiatives.

Downtime is minimized with predictive maintenance powered by intelligent automation. Sensors detect potential equipment failures before they occur, scheduling repairs during off-hours. This proactive strategy keeps production lines running smoothly and avoids costly delays.

Labor costs decrease as intelligent automation takes over routine tasks in manufacturing. Workers shift to higher-value roles, improving overall productivity. This reallocation of human resources supports long-term financial health for manufacturing firms.

Conclusion

Intelligent automation is a game-changer for industrial manufacturing, particularly in rapid manufacturing and metal machining, by driving efficiency and quality. It empowers businesses to produce faster, reduce costs, and maintain high standards with minimal downtime. Embracing this technology ensures manufacturers stay competitive and ready to meet future demands.

-

Legal6 days ago

Legal6 days agoMichigan man JD Vance sentenced to 2 years for threatening Trump and JD Vance

-

Politics1 week ago

Politics1 week agoU.S. to designate Maduro-linked Cartel de los Soles as terrorist organization

-

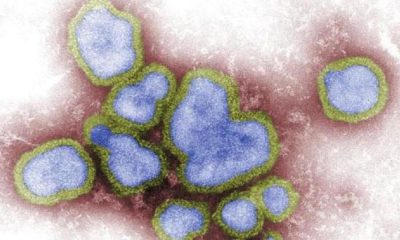

Health7 days ago

Health7 days agoCambodia reports fatal H5N1 bird flu case in 22-year-old man

-

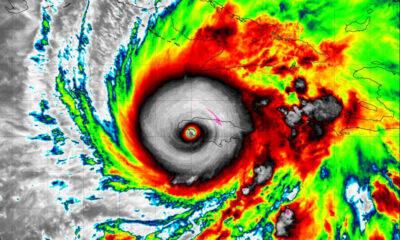

World4 days ago

World4 days agoHurricane Melissa registered 252 mph wind gust, breaking global record

-

Legal4 days ago

Legal4 days agoWoman in critical condition after being set on fire on Chicago train

-

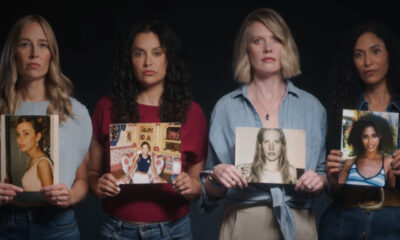

Politics7 days ago

Politics7 days agoEpstein survivors release PSA calling on Congress to release all files

-

Legal4 days ago

Legal4 days ago1 dead, 2 injured in shooting at Dallas Walmart parking lot

-

Legal3 days ago

Legal3 days agoSuspect in San Diego stabbing shot by authorities after fleeing into Mexico