Reviews

Work Order Management Software: Benefits for Operations

The slightest disruption can create ripple effects for companies that rely on smooth maintenance and facility management. A repair request that goes unnoticed or a delayed response to an urgent task can lead to downtime, higher costs, and unhappy employees or tenants. Managing these requests effectively is critical, but many teams still rely on paper logs, emails, or spreadsheets that leave too much room for error.

This is why more companies are exploring work order management software and its benefits for operations as they search for ways to improve reliability and efficiency. Streamlining the entire work order process helps operations teams work smarter and avoid common pitfalls.

Centralizing Requests

Work orders often come from tenants, employees, or internal inspections. Without a central system, requests can be lost in crowded inboxes or forgotten on sticky notes. Software creates a single hub where all work orders are submitted, tracked, and prioritized.

This centralization prevents requests from slipping through the cracks and gives managers a clear view of the overall workload. Instead of reacting in the moment, they can see everything in progress and make better decisions about which tasks need attention first.

Faster Response Times

Speed matters in maintenance. A leaking pipe or malfunctioning air conditioning unit can quickly escalate into bigger problems if not addressed promptly. Work order software makes it easier to respond quickly by sending instant notifications to technicians and providing them with the details they need to start work immediately.

By reducing lag between request and resolution, teams minimize disruptions and improve satisfaction for tenants, employees, or customers who depend on smooth operations.

Clarity for Technicians

Techcians are often tasked with solving complex issues, yet the information they receive is sometimes vague. A handwritten note may say “broken pump,” but without context, the technician wastes time investigating before taking action.

With digital work orders, details such as equipment history, parts needed, and step-by-step instructions can be attached to the task. This transparency allows technicians to come equipped and prepared, finish jobs faster, and reduce the chances of repeat visits for the same issue.

Prioritizing What Matters

Not every request carries the same weight. A lightbulb replacement can wait a day, but a failed elevator in a residential building cannot. Software allows managers to assign priority levels so urgent issues are addressed first.

This prioritization helps teams allocate resources effectively and ensures that minor ones never overshadow critical tasks. Over time, this leads to smoother operations and fewer disruptions.

Reducing Administrative Burden

Paperwork can hamper productivity. Managers and technicians often spend hours creating reports, tracking down signatures, or updating spreadsheets. Work order software automates much of this work. Tasks are logged digitally, updates are tracked automatically, and reports can be generated with a few clicks.

By cutting administrative tasks, staff have more time to focus on maintaining facilities and equipment rather than managing paperwork.

Improving Accountability

In manual systems, it can be difficult to determine who is responsible for a particular task or why a request is delayed. Work order software assigns tasks directly to specific individuals and tracks their progress.

This accountability creates transparency across the team. Managers can see whether a job is in progress or completed, while technicians clearly own their responsibilities. The result is fewer misunderstandings and a stronger sense of responsibility across the team.

Tracking Costs More Accurately

Maintenance budgets are often tight, and unexpected costs can quickly erode margins. Work order software allows managers to attach labor hours, parts used, and vendor costs to each task.

Over time, this data provides a more accurate picture of where money is spent. Managers can identify recurring expenses, negotiate better supplier deals, or adjust staffing to meet demand. Cost visibility makes financial planning less about guesswork and more about data-driven insights.

Supporting Preventive Maintenance

Although work order software is often associated with reactive requests, it also plays a role in preventive maintenance. Managers ensure that equipment receives regular attention by scheduling recurring work orders for inspections and routine service.

This reduces the risk of breakdowns and extends the life of valuable assets. Preventive work orders also provide documentation that can be used for audits or compliance requirements, further strengthening operations.

Final Thoughts

Maintenance and facility operations are too necessary to leave to chance. When requests are missed or delayed, the costs show up in downtime, higher expenses, and dissatisfied tenants or staff. Work order management software provides a way to bring order, visibility, and accountability to these processes.

-

Legal6 days ago

Legal6 days agoMichigan man JD Vance sentenced to 2 years for threatening Trump and JD Vance

-

Politics1 week ago

Politics1 week agoU.S. to designate Maduro-linked Cartel de los Soles as terrorist organization

-

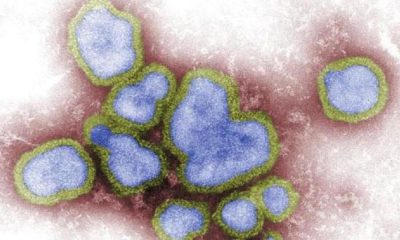

Health7 days ago

Health7 days agoCambodia reports fatal H5N1 bird flu case in 22-year-old man

-

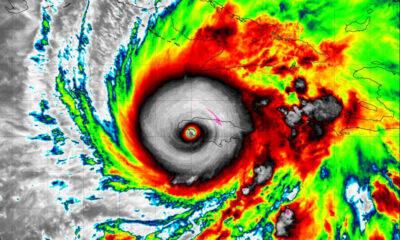

World4 days ago

World4 days agoHurricane Melissa registered 252 mph wind gust, breaking global record

-

Legal4 days ago

Legal4 days agoWoman in critical condition after being set on fire on Chicago train

-

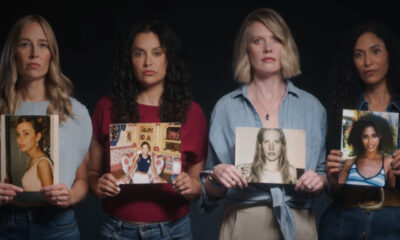

Politics7 days ago

Politics7 days agoEpstein survivors release PSA calling on Congress to release all files

-

Legal4 days ago

Legal4 days ago1 dead, 2 injured in shooting at Dallas Walmart parking lot

-

Legal3 days ago

Legal3 days agoSuspect in San Diego stabbing shot by authorities after fleeing into Mexico