Reviews

6 Ways to Reduce Downtime and Increase Efficiency in Warehousing

Let’s be honest, running a warehouse can feel like a juggling act. Between keeping inventory organized, meeting deadlines, and making sure equipment doesn’t break down at the worst possible moment, it’s a lot to handle. And downtime? It’s the ultimate productivity killer. The good news is that there are some pretty straightforward ways to keep things moving smoothly and save yourself a lot of headaches. When it comes to running a warehouse, there are a number of moving parts to keep track of. But with the right strategies in place, you can cut down on wasted time and boost efficiency. Here are some tips to help you get there.

1. Streamline Material Handling Processes

Have you ever watched a forklift make multiple trips back and forth, moving just one load at a time? It’s exhausting to watch, and even more exhausting for your productivity levels. The first step to reducing downtime is to tackle material handling head-on.

Think about the flow of materials in your warehouse. Is your layout working for you, or against you? Small tweaks, like rearranging high-traffic areas or grouping similar items closer together, can save hours over time. But sometimes, it’s not just about where things are; it’s about how you move them.

This is where equipment upgrades like forklift extensions come in. They can turn a standard forklift into a multitasking powerhouse by allowing it to handle oversized, bulky, or awkwardly shaped loads that wouldn’t normally fit on standard forks. By extending the reach and lifting capacity, they make it possible to transport larger quantities of materials in fewer trips, saving both time and effort. These types of tools help with managing oversized pallets or odd-shaped inventory, and they keep things moving instead of coming to a halt.

2. Stay Ahead With Preventive Maintenance

Nobody wants their equipment to break down mid-shift. Yet, it happens all the time. The fix? Preventive maintenance. Think of your forklifts and other machines like your car. Would you skip an oil change and hope for the best? Probably not. Warehousing equipment needs the same kind of TLC. Regular inspections and maintenance schedules catch small issues before they turn into big problems.

Make a checklist. Track usage hours. Swap out parts before they fail. It’s a simple formula, but it keeps your tools in top shape and avoids those dreaded “out of order” signs.

And don’t forget attachments. These need to be checked, too. A bent extension or loose connection might not seem like a big deal until it slows you down or causes damage. Stay ahead of the game, and you’ll avoid costly downtime.

3. Invest in Employee Training and Safety

Ever seen someone struggle to use equipment they’re not fully trained on? It’s nerve-wracking and dangerous.

Your team is the backbone of your warehouse. But even the best tools won’t save you if your crew isn’t using them properly. That’s why investing in ongoing training pays off big time. When employees know exactly how to handle equipment, they work faster and safer.

Training doesn’t have to be boring, either. Hands-on demos, quick refreshers, and even friendly competitions can keep things interesting while reinforcing skills. Plus, a well-trained team is more confident, and confidence leads to fewer mistakes, and fewer mistakes mean less downtime.

4. Leverage Automation and Smart Technology

Technology is changing the game for warehouses, and ignoring it is like refusing to upgrade from dial-up internet. Why make things harder than they have to be?

Among all the ways to improve productivity, warehouse management systems (WMS) are perhaps one of the most effective. These systems manage inventory, control workflow, and can even place an order for more stock when the level is low. The end result is no more guessing, and less time spent wading through mounds of paperwork.

But then there are intelligent devices. They include sensors that send a message to replace a part, or automate a process, and the automated forklifts that do the heavy work, making your operation run faster. Add to that the fact that versatile tools are easy to come by, and you are in a high-efficiency environment.

5. Make Equipment More Versatile

Here’s the thing, warehouses rarely deal with one type of product. From bulky items to odd shapes, flexibility is key.

Versatile equipment makes life easier. Tools designed to handle oversized or awkward loads allow operations to move more materials in one go, reducing the need for multiple trips. They’re easy to attach, even easier to use, and save time by improving handling efficiency. It’s like giving your machinery a superpower.

And versatility isn’t just about what you can carry. It’s about adaptability. Being able to switch tools quickly means you’re not wasting time waiting for the right machine or moving inventory the hard way.

6. Optimize Inventory Management

Ever spend an hour looking for something you swear was “just there yesterday”? Disorganized inventory is one of the fastest ways to lose time.

Real-time tracking systems can make a world of difference. Scanners and barcodes mean you always know what’s in stock and where it’s stored. Pair that with clear labels and logical layouts, and suddenly finding things isn’t a scavenger hunt, it’s second nature.

But don’t stop there. Regular inventory audits can catch mistakes before they turn into bigger problems. And when you combine smart organization with awesome tools, you can handle larger quantities at once, saving even more time.

Conclusion

In the end, managing a warehouse effectively means that one has to put in less effort and time to get better results. It may seem like simple things such as changing the layout of the warehouse, maintaining equipment, or even incorporating new tools can greatly improve performance.

Think about it, what’s one area in your warehouse that could be running smoother right now? Chances are, the fix isn’t as complicated as it seems. So, why wait? Start making those changes today and watch your downtime disappear.

-

Legal6 days ago

Legal6 days agoMichigan man JD Vance sentenced to 2 years for threatening Trump and JD Vance

-

Politics1 week ago

Politics1 week agoU.S. to designate Maduro-linked Cartel de los Soles as terrorist organization

-

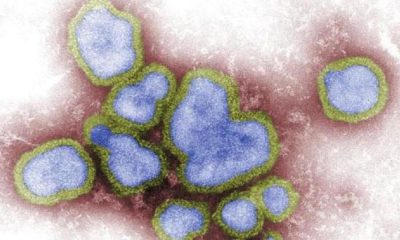

Health7 days ago

Health7 days agoCambodia reports fatal H5N1 bird flu case in 22-year-old man

-

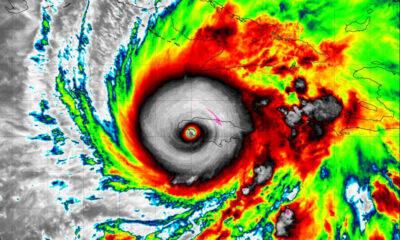

World4 days ago

World4 days agoHurricane Melissa registered 252 mph wind gust, breaking global record

-

Legal4 days ago

Legal4 days agoWoman in critical condition after being set on fire on Chicago train

-

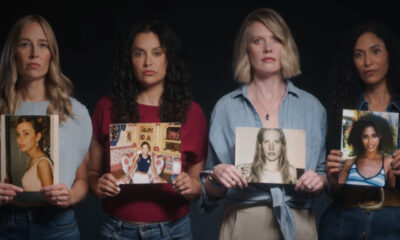

Politics1 week ago

Politics1 week agoEpstein survivors release PSA calling on Congress to release all files

-

Legal4 days ago

Legal4 days ago1 dead, 2 injured in shooting at Dallas Walmart parking lot

-

Legal3 days ago

Legal3 days agoSuspect in San Diego stabbing shot by authorities after fleeing into Mexico