Reviews

Why Smart Businesses Prioritise Industrial Liquid Logistics

In today’s globalised, efficiency-driven economy, the way industries manage their industrial liquid logistics plays a critical role in operational success and regulatory compliance. From agriculture and chemicals to mining and brewing, businesses handling bulk liquids must address not only storage and transportation but also safety, sustainability, and cost-efficiency. Smart businesses understand that getting these logistics right isn’t a luxury—it’s essential.

The Rising Demand for Advanced Liquid Handling

Handling large volumes of liquid presents unique challenges that solid goods simply don’t face. Liquids are prone to spillage, contamination, and chemical reactivity, making the logistics significantly more complex. The increased demand for chemical and liquid transportation in sectors like agriculture and mining is prompting companies to adopt more robust, traceable, and environmentally safe systems.

Moreover, global supply chain pressures and tighter regulations have increased the need for compliant, durable, and versatile storage and transportation solutions. Companies are moving away from traditional drums and tanks, opting instead for Intermediate Bulk Containers (IBCs) that offer flexibility, safety, and economic efficiency.

Intermediate Bulk Containers: A Backbone of Liquid Logistics

IBCs are large containers used to store and transport liquids, semi-solids, and pastes. They come primarily in plastic and stainless steel forms and are a go-to solution for industries that rely on the efficient movement of materials. Their stackable design and modular size make them especially suitable for both storage and transit, allowing businesses to reduce waste and improve handling.

Stainless steel IBCs are particularly advantageous for industries such as brewing and chemicals, where hygiene and chemical compatibility are non-negotiable. These containers are corrosion-resistant, reusable, and capable of maintaining product integrity across long distances and storage periods.

Plastic IBCs, on the other hand, offer cost-effective and lightweight options for non-hazardous and less reactive liquids. When paired with spill containment bunds, they provide an extra layer of protection against accidental leakage—an increasingly important consideration under environmental health and safety (EHS) regulations.

Efficiency and Compliance Go Hand in Hand

Logistics managers are under constant pressure to meet delivery deadlines, minimise costs, and maintain compliance with environmental and safety standards. Modern liquid logistics solutions are designed to help companies meet these goals simultaneously.

Spill containment bunds, for instance, are a regulatory requirement in many jurisdictions and serve as a frontline defence against hazardous leaks. Their inclusion in logistics operations demonstrates a proactive approach to compliance and risk mitigation. For companies handling volatile or reactive substances, managing the dangers of hazardous chemical transport is not only a regulatory necessity but a core element of operational safety.

Additionally, integrating track-and-trace technologies into IBC systems allows for real-time monitoring of location, volume, and condition, enabling proactive decision-making and reducing downtime or losses due to mismanagement.

Environmental Considerations in Liquid Logistics

Sustainability has become a key decision-making factor across all sectors. In industries dealing with bulk liquids—especially chemicals—mitigating environmental impact is crucial. Using reusable containers, investing in long-life materials like stainless steel, and ensuring proper spill management all contribute to reducing a company’s ecological footprint.

Furthermore, businesses are increasingly being evaluated not just by their profit margins but by their Environmental, Social, and Governance (ESG) credentials. A well-managed logistics system that prioritises safety, sustainability, and efficiency helps companies align with broader ESG goals and builds trust with partners, regulators, and consumers.

Why Strategic Planning Matters

Strategic investment in industrial liquid logistics pays off in more ways than one. It minimises product loss, reduces environmental risks, optimises space, and ensures compliance with evolving regulations. For companies transporting sensitive liquids, such as flammable chemicals or perishable food-grade materials, reliable logistics infrastructure is not just beneficial; it is imperative.

Whether through upgrading to more advanced IBCs, implementing automated handling systems, or designing custom bund solutions, companies that plan their logistics with foresight are better positioned to weather disruptions and scale sustainably.

One example in this field is Tank Management Australia, whose range of services and products has helped businesses in critical sectors maintain robust and compliant logistics operations.

More Than Moving From Point A to B

Industrial liquid logistics is not just about moving materials from A to B. It’s about creating a resilient, compliant, and sustainable system that supports business growth while safeguarding people and the planet. For industries dealing with bulk liquids, prioritising logistics means staying ahead of risks, regulations, and inefficiencies—hallmarks of a truly smart business.

-

World3 days ago

World3 days agoEthiopian volcano erupts for first time in thousands of years

-

Legal1 week ago

Legal1 week agoMichigan man JD Vance sentenced to 2 years for threatening Trump and JD Vance

-

Legal1 week ago

Legal1 week agoWoman in critical condition after being set on fire on Chicago train

-

World1 week ago

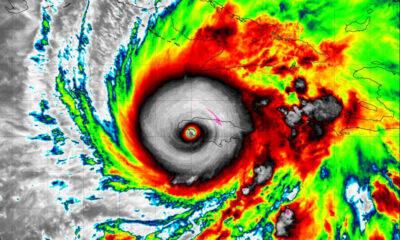

World1 week agoHurricane Melissa registered 252 mph wind gust, breaking global record

-

Legal6 days ago

Legal6 days agoSuspect in San Diego stabbing shot by authorities after fleeing into Mexico

-

Legal1 week ago

Legal1 week ago1 dead, 2 injured in shooting at Dallas Walmart parking lot

-

Health6 days ago

Health6 days agoMarburg virus outbreak in Ethiopia grows to 6 confirmed cases

-

Legal6 hours ago

Legal6 hours agoUtah Amber Alert: Jessika Francisco abducted by sex offender in Ogden