Reviews

Understanding the Steel Fabrication Process: From Design to Delivery

Ever wondered how those skyscrapers seem to touch the sky, or how those bridges are so strong? It all starts with one thing: fabrication in steel. It is basically the backbone of construction and manufacturing, wherein raw steel is turned into what we see around us. Let’s break down how it happens step by step so that the amount of craftsmanship to be seen in every steel beam and column is well worth appreciation.

Initial Design and Planning

First of all, any project would start with a plan. This is where the journey begins, all about understanding the needs and desires of the client. What’s the vision? Sometimes, it feels like deciphering a treasure map, but it’s so important to make sure everyone is on the same page.

When the requirements are clear, then it is time to knock on the drawing board-literally speaking. The detailed blueprint through CAD, in other words Computer-Aided Design if one didn’t know, is drawn by designers and engineers alike. Visualize being able to see a building before it may exist; pretty cool, right? Collaboration is key here: architects, engineers, and fabricators reviewing everything with each other to get it just right.

And materials, let us not forget: the type of steel applied can be a total game-changer. Do we go with carbon steel or stainless steel? What about the weight and durability? These decisions mean so much when it comes to how the structure will hold up over time.

Pre-Fabrication Preparation

With the design in place, it’s now time to get down to serious planning. This also involves project management: setting timelines, budgets, and coordination with suppliers. You can kind of think about it like event planning, where everything has to align.

Next comes material procurement. Here, fabricators source the raw steel they need. Quality is key in this area, and they must pay close attention to inventory so they have everything on hand once production gets underway. Nobody likes delays due to missing materials!

Fabrication Process

Here comes the fun: the actual fabrication! This is where steel goes from flat sheets and beams into something remarkable.

Cutting

First, we cut the steel. Among the many methods out there, some very popular ones are plasma cutting and laser cutting. The precision needs to be just right, or other things are going to be off. You can think about this in terms of trying to cut a cake: you want even pieces, not some kind of lopsided mess!

Forming

Cut, the steel now takes shape. Bending or rolling is involved to make the material fit the design. Now, heavy machinery goes into action, and it’s amazing how this hard piece of steel can be molded with such strength.

Welding

Then comes the welding stage. This literally is where pieces come together, depending on the project, several types may be used such as MIG or TIG. It is in this stage that skilled welders play a critical role in securely bonding things together. Have you ever seen sparks flying? That’s part of the artistry!

Finishing

Finally, we finish the steel: paint and galvanize against rust and wear. A good finish not only makes it look good; it prolongs the life of the steel. After all, who wants to deal with corrosion on a brand-new structure?

Quality Control and Assurance

You may ask yourself, “How do they know everything is up to standard?” That’s a good question. Where quality control comes in is where fabricators have inspections and tests that are necessary for the steel to meet all the safety standards. It is sort of like going to the doctor to get a check-up-everyone wants to be reassured things are tip-top!

Documentation is also vital. Keeping records of materials and processes is important in regard to compliance and traceability. No one wants to look like they are cutting corners in the safety world. If you’re looking for a comprehensive steel fabrication guide, this stage is where many of those best practices are outlined and followed.

Delivery and Installation

All fabricated and tested, now it’s time for the big move. This is where logistics come into play in a very big way. How does one transport those massive steel components? It may involve careful planning: how to safely get a giant beam from shop to site. It’s all about routes, timing, and sometimes just a little bit of creativity!

On-site, coordination is key: the installation team must coordinate with the construction crew for everything to fit perfectly. Safety is of prime importance here, and workers must be kept protected while they are lifting and placing large pieces of steel.

Conclusion

And there you have it! From design to delivery, the fabrication process of steel is a wonder to behold. Each one of these steps plays an important role in giving us the structures that we use every day. The next time you see a building or a bridge, just stop and appreciate the skill and cooperation it took to make it.

-

World6 days ago

World6 days agoEthiopian volcano erupts for first time in thousands of years

-

Legal3 days ago

Legal3 days agoUtah Amber Alert: Jessika Francisco abducted by sex offender in Ogden

-

US News2 days ago

US News2 days agoExplosion destroys home in Oakland, Maine; at least 1 injured

-

Health3 days ago

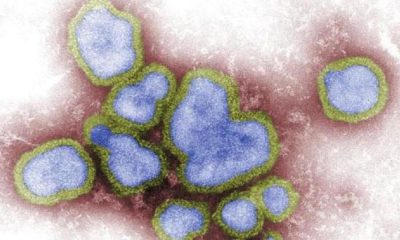

Health3 days agoMexico’s September human bird flu case confirmed as H5N2

-

Legal1 week ago

Legal1 week agoSuspect in San Diego stabbing shot by authorities after fleeing into Mexico

-

Health1 week ago

Health1 week agoMarburg virus outbreak in Ethiopia grows to 6 confirmed cases

-

World1 week ago

World1 week agoU.S. sanctions companies and vessels accused of aiding Iranian military oil sales

-

World3 days ago

World3 days agoWoman killed, man seriously injured in shark attack on Australia’s NSW coast