Reviews

Global Supply Chain Shakeups: How Chinese Manufacturers Are Adapting in 2025

In 2025, global manufacturing continues to feel the aftershocks of pandemic-related disruptions, shifting geopolitical landscapes, and rapidly advancing technologies. While industries in many parts of the world struggle to regain equilibrium, China remains front and center, playing a pivotal role in shaping the present and future of manufacturing. Evolving consumer demands, new sustainability targets, and intensifying global competition are driving Chinese manufacturers to embrace unprecedented levels of innovation.

Global Supply Chain Disruptions

Fluctuating shipping costs, shortages in raw materials, and shifting trade policies have created a new normal for companies worldwide. Many are finding that the stable, predictable supply chain networks of the past no longer exist. In Guangdong—a region often regarded as the heart of China’s manufacturing sector—business leaders have been compelled to rethink production timelines and strategies.

According to Ant Liang, Chief Executive Officer at Promax, a Guangdong-based pogo pin manufacturer recognized as a national New High-tech enterprise, these disruptions are also opportunities. “We saw early on that relying on traditional models could leave us exposed to sudden bottlenecks. That realization pushed us to invest in faster prototyping cycles and more robust quality controls,” he says.

Adapting Through Innovation

Across China’s industrial sphere, adaptation is visible in the widespread adoption of automation, artificial intelligence, and lean manufacturing principles. Advanced robotics streamline assembly lines, while integrated data analytics platforms help manufacturers respond rapidly to market signals.

Promax is one such company that has embraced next-level research and development. Liang notes that bringing processes in-house—from design to production—has accelerated development timelines and reduced vulnerabilities. By leveraging cutting-edge engineering and adopting quick turnaround methods, manufacturers throughout Guangdong are setting a new bar for operational resilience.

Regional Advantages and Challenges

Guangdong offers distinct advantages that have helped it maintain a competitive edge. A robust infrastructure, abundant skilled labor, and supportive local policies make it an attractive hub for high-tech manufacturing. Government incentives encourage research and development, keeping pace with the global push for advanced manufacturing solutions.

At the same time, the region is not without its hurdles. Rising labor costs and intense competition for engineering talent create pressure to evolve quickly. Liang points out that companies like Promax must consistently invest in employee training and state-of-the-art equipment. “Our business grows with our people,” he explains. “Investing in their skills and well-being goes hand in hand with expanding our technological capabilities.”

Looking Ahead: Global Impact

As China’s manufacturing ecosystem expands and refines its strategies, the effects ripple across borders. The enhanced efficiency and reliability of supply chains within Guangdong can reduce lead times and pricing volatility for overseas partners. With rising demand for sustainable materials and ethical labor practices, Chinese manufacturers that adapt quickly stand to gain trust on the international stage.

Still, many industries beyond China continue to feel the knock-on effects of each supply chain pivot, underscoring how interdependent global markets have become. “Whether it’s components for consumer electronics or specialized connectors for medical devices, we’re all operating in a tightly woven ecosystem,” Liang says.

Conclusion

In an era defined by unpredictability, China’s manufacturing powerhouse has demonstrated resilience through innovation and strategic thinking. Guangdong’s evolving approach—emphasizing advanced technology, skilled workforce development, and proactive leadership—offers a blueprint for other regions grappling with similar challenges.

Leaders like Ant Liang represent a new generation of visionaries, prepared to adapt quickly to whatever disruptions come next. As global supply chains continue to shift, the success stories emerging from China’s industrial heartland provide clues to how manufacturers worldwide might stay agile and competitive in the years to come.

-

World1 week ago

World1 week agoEthiopian volcano erupts for first time in thousands of years

-

Legal5 days ago

Legal5 days agoUtah Amber Alert: Jessika Francisco abducted by sex offender in Ogden

-

US News5 days ago

US News5 days agoExplosion destroys home in Oakland, Maine; at least 1 injured

-

Health5 days ago

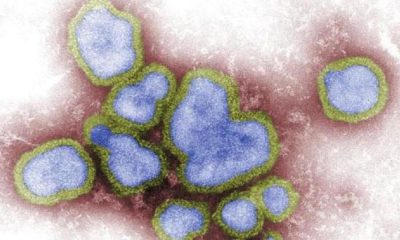

Health5 days agoMexico’s September human bird flu case confirmed as H5N2

-

Health12 hours ago

Health12 hours ago8 kittens die of H5N1 bird flu in the Netherlands

-

Legal2 days ago

Legal2 days ago15 people shot, 4 killed, at birthday party in Stockton, California

-

World6 days ago

World6 days agoWoman killed, man seriously injured in shark attack on Australia’s NSW coast

-

Health4 days ago

Health4 days agoMarburg outbreak in Ethiopia rises to 12 cases and 8 deaths