Reviews

Guide to Used Pallet Racking: Smart, Sustainable Warehouse Solutions

Used pallet racking presents a compelling option for growing warehouses, offering cost savings, flexibility, and environmental benefits without compromising quality. But navigating the used rack market requires careful vetting to ensure safety, compatibility, and long-term value. Here’s your in-depth guide to buying, installing, and maintaining used pallet rack systems.

Why Consider Used Pallet Racking?

Significant Cost Savings

Used racks can cost 30–50% less than new ones, helping budget-conscious operations expand storage affordably

Immediate Availability

No manufacturing lead times—many used rack systems are ready for fast loading and installation.

Environmental Sustainability

Reusing steel reduces waste and demand for new materials, making used racks an eco-friendly choice.

Identifying High-Quality Used Racking

A successful purchase begins with spotting quality in used components:

- Visual Integrity: Minimal bends, dents, and rust, especially on uprights and beams.

- Compatibility: Teardrop-style racks are versatile and widely used; ensure beam depths and frame spacing match your system.

- Manufacture Labels: Brand stamps verify rated load capacity, models, and compliance—vital for safety certifications.

What to Inspect Before Buying

Structural Integrity

Avoid racks with compromised structural members. Even small damage to uprights can critically weaken the system.

Brand Compatibility

Confirm that racks match your existing system components—mixing brands can cause misalignments and load issues.

Functional Fit

Confirm dimensions: verify upright depths and beam lengths with warehouse measurements. A slight mismatch (even 0.5″) can disrupt alignment.

Condition Verification

Obtain photos and videos. Look for signs of improper repair—bolted uprights or mismatched beams signal potential safety hazards.

Key Considerations When Buying

- Supplier Reputation: Choose reputable vendors who inspect, refurbish, and certify their material.

- Budget Planning: Include costs for transport, installation, potential shims, column protectors, and refinish work.

- Future Proofing: Can the racks expand with your operation? Choose systems with modular attachments and adjustable beam levels.

Types of Used Pallet Racking Available

- Selective (Single‑Deep) Racks: Offers full accessibility—great for mixed SKUs and dynamic inventory.

- Teardrop Style: Tool-free assembly, ideal for quick reconfigurations and easy expansion.

- Double‑Deep, Drive‑In/Through: Higher density but lower selectivity—suited for uniform, bulk storage needs.

Installation and Safety Essentials

Professional Setup

Even used racks must be installed by pros to ensure levels, alignment, and anchor placement. Local codes may require stamped plans .

Ongoing Inspections

Regular audits—looking for damage, rust, missing parts—are crucial. OSHA and RMI standards stress the importance of ongoing maintenance.

Protective Measures

Install column protectors, rack guards, and shims on uneven floors to protect upright integrity.

Safety Comparison of Used vs. New Racks

| Feature | Used Racks | New Racks |

| Upfront Cost | Lower (30–50% savings) | Higher initial investment |

| Availability | Often in stock ready to install | Longer lead time & custom build |

| Material Condition | Varies (must inspect) | Brand new with full warranties |

| Environmental Impact | Eco-friendly reuse | Higher manufacturing resource demand |

| Maintenance Needs | May require refurbishing | Minimal initial maintenance |

Tips for Smart Purchasing

- Pre-Plan Layout: Measure your space and sketch bay and beam configurations.

- Require Visual Proof: Photos or videos help catch hidden defects early.

- Check Documentation: Beam capacity charts and stamped labels are essential.

- Select Trusted Vendors: Look for reviews and inspect vendor reputation.

- Budget Holistically: Include costs beyond purchase—installation, safety upgrades, refurbishing.

Optimizing ROI from Used Racking

- Increase Load Density: Consider double-deep or multi-tier racks when appropriate.

- Future Updates: Modular systems let you scale up later.

- Efficient Layouts: Use selective racks for fast-movers; compact systems for bulk items.

- Upright Safety: Deploy column guards wherever forklifts operate.

- Regular Safety Audits: Schedule inspections every quarter, or more frequently in heavy-use environments.

Final Takeaway: A Strategic Investment

Used pallet racking can be a powerful asset if selected and managed strategically. The benefits are clear: lower costs, faster installation, and sustainability. But successful implementation takes thorough inspection, expert installation, and proactive safety oversight.

With rigorous vetting, quality parts, and professional support, used racking can perform reliably for years. It’s not just about saving money—it’s about getting a smarter storage solution that serves your operation today and scales with your growth tomorrow.

-

World1 week ago

World1 week agoEthiopian volcano erupts for first time in thousands of years

-

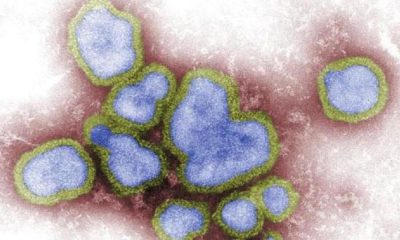

Health2 days ago

Health2 days ago8 kittens die of H5N1 bird flu in the Netherlands

-

Legal7 days ago

Legal7 days agoUtah Amber Alert: Jessika Francisco abducted by sex offender in Ogden

-

US News6 days ago

US News6 days agoExplosion destroys home in Oakland, Maine; at least 1 injured

-

Health6 days ago

Health6 days agoMexico’s September human bird flu case confirmed as H5N2

-

Legal3 days ago

Legal3 days ago15 people shot, 4 killed, at birthday party in Stockton, California

-

World7 days ago

World7 days agoWoman killed, man seriously injured in shark attack on Australia’s NSW coast

-

Health6 days ago

Health6 days agoMarburg outbreak in Ethiopia rises to 12 cases and 8 deaths