Reviews

From Inventory to Shipping: How to Enhance Warehouse Operations and Facility Performance

Warehouse operations play a pivotal role in the efficiency of supply chains, affecting everything from inventory management to shipping. As businesses strive to meet growing demands, optimizing warehouse processes becomes essential for improving performance and profitability. Effective management of resources like inventory, order picking, and packing is crucial for minimizing delays and ensuring smooth operations.

In this article, we’ll explore practical ways to enhance warehouse operations and performance, from inventory management to shipping efficiency.

Here’s what you need to know:

Understanding the Basics of Warehouse Operations

A well-functioning warehouse is the backbone of any distribution operation. It’s where goods are stored, sorted, and prepared for shipping, making it a critical part of the supply chain. The basic components of warehouse operations include inventory management, order picking, packing, and shipping. Each of these elements requires careful attention to ensure goods move smoothly and efficiently. By focusing on optimizing these processes, companies can reduce operational costs, minimize errors, and ensure fast delivery times.

Efficient warehouse operations can also improve customer satisfaction by ensuring accurate order fulfillment and timely delivery. Streamlining these processes starts with organizing the warehouse layout, investing in the right technology, and properly training staff. A well-run warehouse not only helps businesses meet customer expectations but also supports long-term growth by improving resource allocation and workflow efficiency.

Optimizing Inventory Management

Inventory management is one of the most critical aspects of warehouse operations. Maintaining an accurate inventory helps prevent stockouts, overstocking, and other costly mistakes. One effective way to improve inventory management is through the use of a warehouse management system (WMS), which tracks the movement of goods in real time, providing accurate and up-to-date information.

In addition to technology, businesses can also optimize their inventory management by using temporary storage options from a reliable storage solutions provider. When inventory exceeds regular storage capacity, flexible solutions like shipping containers for rent can provide the extra space needed to keep operations running smoothly. These containers are a cost-effective way to handle excess stock without the need for permanent expansion. With the right strategy, businesses can maintain inventory accuracy while improving efficiency.

Enhancing Order Picking Efficiency

Order picking is the process of selecting products from inventory to fulfill customer orders. It’s a critical step in the warehouse workflow and can significantly impact the speed and accuracy of shipments. There are several picking methods, such as single order picking, batch picking, and zone picking, each suited for different types of orders.

By investing in the right technology and processes, businesses can speed up order picking. For example, barcode scanning and voice-directed picking systems can reduce human error and increase the speed at which orders are processed. Additionally, simplifying the layout and grouping similar items together can help pickers move more efficiently, minimizing travel time within the warehouse.

The Importance of Packing and Labeling

Once items have been picked, they must be packed and labeled for shipping. Efficient packing and labeling are essential for minimizing shipping errors and ensuring that products arrive at the correct destination in good condition. Proper packing protects goods during transit, while accurate labeling ensures that each item is sent to the right location.

To improve packing efficiency, businesses should standardize packing procedures, use the appropriate packing materials, and employ automated packing systems where possible. Additionally, having a clear labeling system in place can prevent delays and errors, ensuring that shipments leave the warehouse in a timely manner.

Improving Warehouse Layout

A well-organized warehouse layout is crucial for optimizing operations. By designing the space effectively, businesses can minimize the time spent searching for products and reduce unnecessary movement within the warehouse. The key is to create designated areas for receiving, storage, picking, packing, and shipping.

A good layout also facilitates smooth traffic flow, helping employees move quickly and efficiently between tasks. For example, placing high-demand items near the packing area can reduce the time spent picking. Furthermore, using clear signage and color-coded zones can make it easier for workers to navigate the space, improving overall efficiency.

Enhancing warehouse operations is essential for businesses aiming to stay competitive in today’s fast-paced market. By optimizing inventory management, improving order picking and packing processes, and leveraging automation and technology, businesses can increase efficiency and reduce operational costs. Additionally, workforce training, performance monitoring, and managing seasonal demand can further boost productivity.

Sustainability also plays a vital role in warehouse operations, with businesses increasingly adopting eco-friendly practices that benefit both the environment and the bottom line. Flexible solutions, such as renting shipping containers for temporary storage, provide an affordable way to manage inventory and streamline operations during peak periods.

By continuously evaluating and improving these areas, businesses can ensure that their warehouse operations are as efficient and cost-effective as possible, setting the stage for long-term success.

-

World1 week ago

World1 week agoEthiopian volcano erupts for first time in thousands of years

-

Health2 days ago

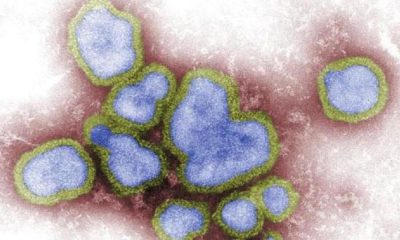

Health2 days ago8 kittens die of H5N1 bird flu in the Netherlands

-

Legal7 days ago

Legal7 days agoUtah Amber Alert: Jessika Francisco abducted by sex offender in Ogden

-

US News6 days ago

US News6 days agoExplosion destroys home in Oakland, Maine; at least 1 injured

-

Health6 days ago

Health6 days agoMexico’s September human bird flu case confirmed as H5N2

-

Legal3 days ago

Legal3 days ago15 people shot, 4 killed, at birthday party in Stockton, California

-

World7 days ago

World7 days agoWoman killed, man seriously injured in shark attack on Australia’s NSW coast

-

Health6 days ago

Health6 days agoMarburg outbreak in Ethiopia rises to 12 cases and 8 deaths