Reviews

A Comparison of Handheld vs. Fixed Metrology Equipment

When it comes to measurement tasks, choosing the metrology tools is essential. Handheld and stationary alternatives each come with benefits catering to various needs across different sectors. Knowing the distinctions between these instruments can enable industries to make informed choices, resulting in enhanced productivity and precision.

The Versatility of Portable Devices

Thanks to their portability, handheld metrology equipment offers remarkable versatility. They allow users to measure objects on-site without the need for relocation, which is especially beneficial for handling large or cumbersome items that are difficult to move. Additionally, human-operated tools can access hard-to-reach areas, making them ideal for detailed inspections.

These tools commonly have capabilities that make data transfer smooth and effortless to manage tasks efficiently by enabling teams to exchange measurements with each other as needed for improved productivity and streamlined operations. Additionally, portable devices often have user interfaces that make it easier for new operators to learn how to use them, reducing downtime.

The Durability of Machinery

Accurate metrology tools are well known for their precision and reliability. Measurement accuracy is essential for precise tasks where external influences are minimised.

Fixed systems offer stability that helps prevent measurement errors caused by movement or vibration levels. These setups often have automated functions that make tasks more efficient and boost productivity. Automation also helps reduce mistakes and improve project outcomes.

Budgetary Concerns

When assessing expenses for a project or purchase decision, it’s important to consider both the immediate and long-term costs involved. Portable gadgets typically have a low or affordable cost, which may be attractive for smaller businesses or those on a tight budget. Nonetheless, it’s essential to consider the maintenance requirements and potential calibration needs.

Established systems may require an investment but usually come with long-lasting performance and strength benefits. The accuracy and automated features provided by configurations can result in cost reductions in the future. Decreased error rates and improved productivity could balance out the strain over time.

Cost Considerations

Various types of tasks call for measurement methods to be employed; handheld tools are particularly useful in situations where mobility is essential, like conducting on-site inspections or fieldwork activities. Sectors such as construction or aerospace find these instruments beneficial due to their adaptability to a range of assignments.

On the other hand, stationary machinery is ideal for tasks that require consistent measurements at a large scale. Industries such as manufacturing and automotive heavily depend on these systems for their accuracy and stability. These tools play a key role in quality assurance by upholding standards during manufacturing procedures.

Advances in Technology

Technological advancements constantly change the field of metrology. Portable gadgets frequently integrate advanced functions, such as augmented reality, to enhance both the user experience and the accuracy of measurements. These new developments allow operators to view data in real-time and improve their decision-making abilities.

Improved systems also reap the advantages of technological advancements as they become integrated with manufacturing processes for enhanced efficiency and streamlined workflow through automation and connectivity features that facilitate smooth incorporation into larger systems.

Enhancing Training and User Interaction

When choosing equipment for a task, consider how easy it is to operate and train. Handheld tools usually come with user interfaces, making it easier for users to interact with them. This simplicity helps cut down on training hours, enabling teams to master the tools. In industries where staff turnover is common, this benefit becomes particularly valuable.

Structured systems may require setups but typically include thorough training sessions so that users can grasp their nuances effectively and derive optimal outcomes from their use.

The Effects on the Environment

Lately, importance has been placed on considering the effects of choosing equipment. Having a footprint due to their portability makes handheld devices a good fit for sustainability objectives by encouraging the right use of resources.

Stable systems are known to use up resources and can streamline operations to cut down on wastage effectively. Incorporating automated functions helps promote sustainability by decreasing errors and enhancing productivity. The extended lifespan of fixed machinery further promotes eco-friendly practices by lessening the necessity for frequent upgrades.

Conclusion

Deciding between handheld and stationary metrology gear depends heavily on requirements, financial limitations, and the specific demands of the task at hand. Handheld devices provide adaptability and simplicity in operation, whereas fixed setups focus more on accuracy and consistency. By considering these aspects, industries can choose gear that matches their goals, improving efficiency and precision in measurement duties. Industries can enhance productivity through well-thought-out choices and ensure their metrology needs are adequately addressed.

-

World1 week ago

World1 week agoEthiopian volcano erupts for first time in thousands of years

-

Health2 days ago

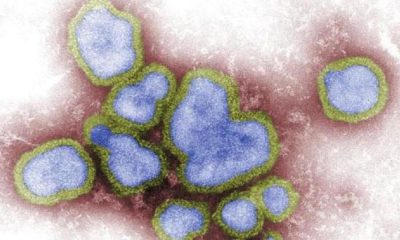

Health2 days ago8 kittens die of H5N1 bird flu in the Netherlands

-

Legal7 days ago

Legal7 days agoUtah Amber Alert: Jessika Francisco abducted by sex offender in Ogden

-

US News6 days ago

US News6 days agoExplosion destroys home in Oakland, Maine; at least 1 injured

-

Health7 days ago

Health7 days agoMexico’s September human bird flu case confirmed as H5N2

-

Legal3 days ago

Legal3 days ago15 people shot, 4 killed, at birthday party in Stockton, California

-

World7 days ago

World7 days agoWoman killed, man seriously injured in shark attack on Australia’s NSW coast

-

Health6 days ago

Health6 days agoMarburg outbreak in Ethiopia rises to 12 cases and 8 deaths