Reviews

How Small Businesses Benefit from a 3PL Service with an Advanced Warehouse System

Managing logistics can be a complex challenge for businesses, especially when scaling operations. Partnering with a 3PL provider equipped with an advanced warehouse system offers substantial advantages that streamline logistics, enhance efficiency, and support growth.

Faster Order Processing

An advanced 3pl warehouse system enhances the speed of order processing by utilising automation and efficient workflows. Orders are picked, packed, and shipped faster, reducing delays and ensuring customers receive products promptly. This acceleration helps businesses meet demand spikes while maintaining reliable service. Automated picking technologies, such as robotic arms and conveyor systems, significantly reduce human errors and ensure consistency.

Accurate Inventory Tracking

These systems enable precise inventory tracking, minimising the risk of overstocking or running out of stock. Real-time data updates allow businesses to have an accurate picture of inventory levels at all times. This reduces errors and improves decision-making, enhancing overall operational efficiency. Barcode scanning and RFID technology further enhance tracking accuracy by automating the identification and recording of inventory movements.

Optimised Storage Solutions

Efficient storage is vital for maximising space and reducing costs. With updated technology, warehouse layouts are optimised to ensure products are stored in accessible locations. This minimises the time and resources needed for retrieval and keeps operations running smoothly. Slotting optimisation software ensures that high-demand items are placed strategically for faster picking.

Reduced Operational Costs

Using an advanced system often reduces labour costs, errors, and inefficiencies. Automation and streamlined processes reduce the need for manual tasks, while better tracking systems reduce losses from misplaced items. This results in significant savings, allowing businesses to allocate resources elsewhere. The use of energy-efficient equipment and optimised layouts also reduces utility and overhead costs.

Improved Stock Management

Keeping track of stock can be challenging without the right tools. An advanced warehouse system provides robust stock management capabilities, such as forecasting tools and automatic alerts for low inventory. These features help businesses avoid stockouts and maintain seamless operations. Machine learning algorithms embedded in these systems can predict trends and improve procurement strategies. Hence, such systems:

- Avoid overstocking by using data-driven forecasting tools

- Prevent stockouts with timely inventory alerts

- Enhance supplier coordination through accurate data sharing

By addressing these aspects, stock levels are balanced effectively, improving supply chain reliability. Advanced replenishment systems further ensure optimal inventory levels by automating order placement with suppliers.

Smooth Integration with Technology

Integration with other technology platforms, such as order management systems and shipping software, is a major benefit. This connectivity creates a unified process from receiving orders to delivery, ensuring all steps are executed without bottlenecks or miscommunication. API-enabled integration ensures smooth data exchange, thus reducing manual input and increasing accuracy.

Real-Time Data Access

Advanced warehouse systems provide real-time insights into inventory, orders, and overall performance. This transparency allows businesses to identify inefficiencies quickly and make informed decisions. Access to up-to-date information helps ensure responsiveness to market changes and customer needs. Dashboards equipped with predictive analytics enable proactive decision-making to address potential disruptions.

Enhanced Supply Chain Visibility

Visibility across the supply chain is crucial for maintaining control and ensuring efficiency. Advanced systems provide detailed insights into each stage of the process, from supplier deliveries to customer shipments. This clarity supports better coordination and ensures on-time deliveries. Real-time GPS tracking of shipments enhances oversight and reduces delays caused by unexpected disruptions.

Hence, hiring a provider with an advanced 3pl warehouse system service offers businesses significant operational and financial advantages. From faster processing to improved stock control and reduced costs, these systems provide the tools needed to enhance logistics efficiency.

-

World1 week ago

World1 week agoEthiopian volcano erupts for first time in thousands of years

-

Health2 days ago

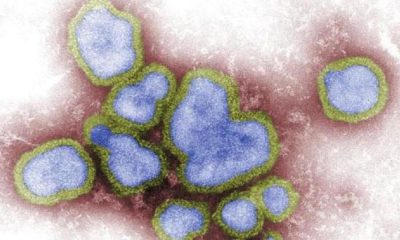

Health2 days ago8 kittens die of H5N1 bird flu in the Netherlands

-

Legal7 days ago

Legal7 days agoUtah Amber Alert: Jessika Francisco abducted by sex offender in Ogden

-

US News6 days ago

US News6 days agoExplosion destroys home in Oakland, Maine; at least 1 injured

-

Health7 days ago

Health7 days agoMexico’s September human bird flu case confirmed as H5N2

-

Legal3 days ago

Legal3 days ago15 people shot, 4 killed, at birthday party in Stockton, California

-

World7 days ago

World7 days agoWoman killed, man seriously injured in shark attack on Australia’s NSW coast

-

Health6 days ago

Health6 days agoMarburg outbreak in Ethiopia rises to 12 cases and 8 deaths