Reviews

The Ultimate Checklist for Upgrading Your Warehouse in 2025

Warehouses are no longer just static storage spaces; they are the backbone of efficient supply chain operations. With e-commerce booming, consumer expectations rising, and competition intensifying, upgrading your warehouse in 2025 has become essential for staying ahead. Modern warehouses must balance advanced technology, optimized layouts, and sustainable practices to keep pace with demand while minimizing costs.

This comprehensive checklist will walk you through the key areas of focus to ensure your warehouse meets today’s challenges and positions itself for future success. Whether you are looking to automate processes, improve safety, or adopt energy-efficient systems, these actionable insights will help you take your facility to the next level.

1. Evaluate Your Current Layout and Space Utilization

An effective warehouse begins with a well-organized layout. Poor space utilization can lead to inefficiencies, higher operational costs, and safety hazards.

- Conduct a detailed space audit: Measure your existing storage capacity and identify bottlenecks. Are the aisles too narrow for equipment? Are shelves too widely spaced, wasting precious real estate?

- Invest in modular storage solutions: Vertical storage systems, such as mezzanines or automated vertical lift modules, can increase capacity without expanding your warehouse footprint.

- Incorporate trash hoppers: Strategically placing trash hoppers, such as the ones provided by Iron Bull Manufacturing, throughout your facility can help manage waste efficiently, prevent clutter, and keep work areas clear for smoother operations.

- Create designated zones: Separate areas for receiving, storage, picking, and shipping to streamline workflow. Use floor markings and signage to enhance organization and minimize errors.

- Plan for scalability: Ensure your layout can accommodate future expansions or product line changes without major disruptions.

2. Integrate Advanced Warehouse Management Systems (WMS)

Technology drives efficiency in modern warehouses, and a robust Warehouse Management System (WMS) is the cornerstone of effective operations.

Upgrade to AI-powered WMS: These systems can analyze historical data to optimize inventory levels, predict demand, and recommend the best storage locations for specific items.

Leverage real-time tracking: Ensure your WMS supports passive RFID tracking or barcode scanning to provide instant visibility into inventory and shipments.

Enable multi-channel integration: A good WMS should seamlessly connect with e-commerce platforms, transportation management systems, and Enterprise Resource Planning (ERP) software for streamlined operations.

Customize workflows: Tailor your WMS to suit the specific needs of your warehouse, from managing temperature-sensitive goods to coordinating multiple delivery schedules.

3. Incorporate Automation and Robotics

Automation is no longer a luxury—it’s a necessity for improving accuracy, speed, and cost-effectiveness.

- Deploy Automated Guided Vehicles (AGVs): These robots transport goods between locations, reducing reliance on forklifts and manual labor.

- Install robotic picking systems: Robots equipped with AI and vision technology can pick items faster and with fewer errors than human workers.

- Upgrade conveyor systems: Invest in modular, scalable conveyor systems that can adapt to changes in your product mix and order volume.

- Automate repetitive tasks: Use robotics for activities such as palletizing, shrink-wrapping, and sorting to free up your workforce for more strategic tasks.

4. Enhance Workforce Efficiency

Your employees are as vital as your technology. Ensuring their safety, comfort, and productivity should be a top priority.

- Invest in ongoing training: Equip workers with the skills to operate new technologies and handle specialized tasks. Provide regular refreshers to keep them updated.

- Improve ergonomics: Install height-adjustable workstations, anti-fatigue mats, and lifting aids to reduce strain and workplace injuries.

- Adopt wearable technology: Devices like smart glasses or wearable scanners can improve picking accuracy and enhance communication across teams.

- Promote a positive work environment: Foster collaboration and open communication to ensure employees feel valued and motivated.

5. Upgrade Safety Measures

A safe warehouse is a productive warehouse. Modern safety practices go beyond compliance and focus on proactive risk prevention.

- Install advanced sensors: Use IoT-enabled devices to monitor for potential hazards such as overheating equipment, spills, or unauthorized personnel access.

- Automate safety protocols: AI-driven systems can detect unsafe conditions and trigger alerts or shutdowns to prevent accidents.

- Conduct regular inspections: Establish a schedule for checking equipment, storage systems, and safety devices. Address any issues immediately.

- Provide clear safety training: Ensure every team member understands emergency procedures, proper equipment usage, and hazard identification.

6. Adopt Energy-Efficient Practices

Sustainability is more than a trend—it’s a business imperative. Reducing energy consumption lowers costs and supports your corporate responsibility goals.

- Switch to energy-efficient lighting: LED and motion-activated lights not only save electricity but also enhance visibility and safety.

- Install renewable energy systems: Solar panels or wind turbines can significantly cut utility costs while reducing your carbon footprint.

- Optimize HVAC systems: Modern climate control systems can maintain consistent temperatures while using less energy, ensuring the safety of temperature-sensitive goods.

- Monitor energy usage: Use smart meters and analytics tools to identify and address areas of inefficiency.

- Consider financing options: Major upgrades like installing solar panels, overhauling HVAC systems, or retrofitting insulation can require significant upfront investment. Using a commercial bridge loan can help cover these costs as part of a larger renovation or expansion, so you can move forward without delaying your sustainability goals.

7. Optimize Inventory Management

Inventory management is at the heart of efficient warehouse operations. Poor practices lead to overstocking, stockouts, and wasted resources.

- Adopt RFID and IoT technologies: These tools provide real-time data on inventory levels, movement, and location, reducing errors and improving accuracy.

- Implement predictive analytics: Use AI to analyze trends and forecast demand, ensuring you always have the right products in stock.

- Enhance returns management: A streamlined process for handling returns reduces delays and keeps inventory accurate.

8. Focus on Sustainability

Consumers and partners increasingly value businesses that prioritize sustainability. Aligning your warehouse practices with eco-friendly principles can enhance your reputation and bottom line.

- Minimize waste: Introduce recycling programs for packaging materials and encourage the use of reusable pallets and containers.

- Choose sustainable materials: Invest in durable, recyclable materials for storage systems and other infrastructure.

- Certify your operations: Achieving green certifications like LEED can validate your sustainability efforts and attract eco-conscious customers.

9. Improve Technology Integration

A connected warehouse is an efficient warehouse. Ensure all systems work together seamlessly for optimal performance.

- Leverage IoT devices: Sensors and smart devices can monitor equipment health, inventory conditions, and operational metrics in real-time.

- Use cloud-based platforms: Centralized data access ensures consistent and accurate information for all stakeholders.

- Strengthen cybersecurity: Protect sensitive data from breaches with robust encryption, firewalls, and regular security updates.

10. Review Vendor and Partner Relationships

Strong partnerships are essential for smooth operations. Regularly evaluate your relationships to ensure they continue to add value.

- Assess vendor performance: Use metrics like delivery times, error rates, and cost-effectiveness to measure success.

- Negotiate better terms: Look for opportunities to reduce costs or improve service levels through renegotiation.

- Collaborate on innovation: Work with vendors to co-develop solutions tailored to your unique challenges and goals.

Conclusion

Upgrading your warehouse in 2025 isn’t just about adopting the latest gadgets or reorganizing shelves; it’s about creating a dynamic, efficient, and future-ready operation that meets the demands of a rapidly evolving market. By following this checklist, you can identify areas for improvement and implement solutions that drive long-term success. From leveraging cutting-edge technology to fostering sustainability and enhancing employee well-being, every step you take brings you closer to a more efficient and competitive warehouse.

Start today, prioritize what aligns with your goals, and embrace the changes that will propel your business into a brighter, more productive future.

-

World1 week ago

World1 week agoEthiopian volcano erupts for first time in thousands of years

-

Health2 days ago

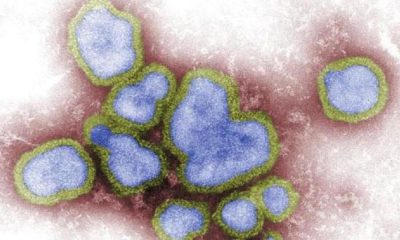

Health2 days ago8 kittens die of H5N1 bird flu in the Netherlands

-

Legal7 days ago

Legal7 days agoUtah Amber Alert: Jessika Francisco abducted by sex offender in Ogden

-

US News6 days ago

US News6 days agoExplosion destroys home in Oakland, Maine; at least 1 injured

-

Health7 days ago

Health7 days agoMexico’s September human bird flu case confirmed as H5N2

-

Legal3 days ago

Legal3 days ago15 people shot, 4 killed, at birthday party in Stockton, California

-

World7 days ago

World7 days agoWoman killed, man seriously injured in shark attack on Australia’s NSW coast

-

Health6 days ago

Health6 days agoMarburg outbreak in Ethiopia rises to 12 cases and 8 deaths